Power Hall

Carmody Groarke has completed the refurbishment of the Power Hall at Manchester’s Science and Industry Museum, combining heritage restoration with decarbonisation measures to create a more accessible and environmentally efficient museum.

Photos

Federico Ferinatti, Lee McClean PA Media Assignments

Originally constructed in 1855 as a shipping shed for the world’s first inter-city steam-powered passenger railway, the Grade II listed Power Hall is one of the most significant surviving buildings of the industrial revolution. Following a six-year closure for urgent repairs, the building has reopened as the Andrew Law Gallery, home to one of the UK’s largest collections of working steam, gas and electric engines.

The Power Hall forms part of a wider regeneration of the Science and Industry Museum’s seven-acre site. The masterplan aims to repair and decarbonise the museum’s historic buildings while improving public access and connections to Manchester’s growing cultural quarter, including nearby Aviva Studios.

Carmody Groarke’s work reinstates the clarity of the 108-metre-long hall, revealing the rhythm of its historic timber trusses and dividing the space into two parallel bays. A new central entrance aligns with the east–west axis of the original goods shed, establishing a clear route through the museum site from the New Warehouse and Upper Yard into the Power Hall. As a result, visitors now enter at the centre of the building, where sightlines extend west towards railway rolling stock and east towards the steam engines.

Site plan.

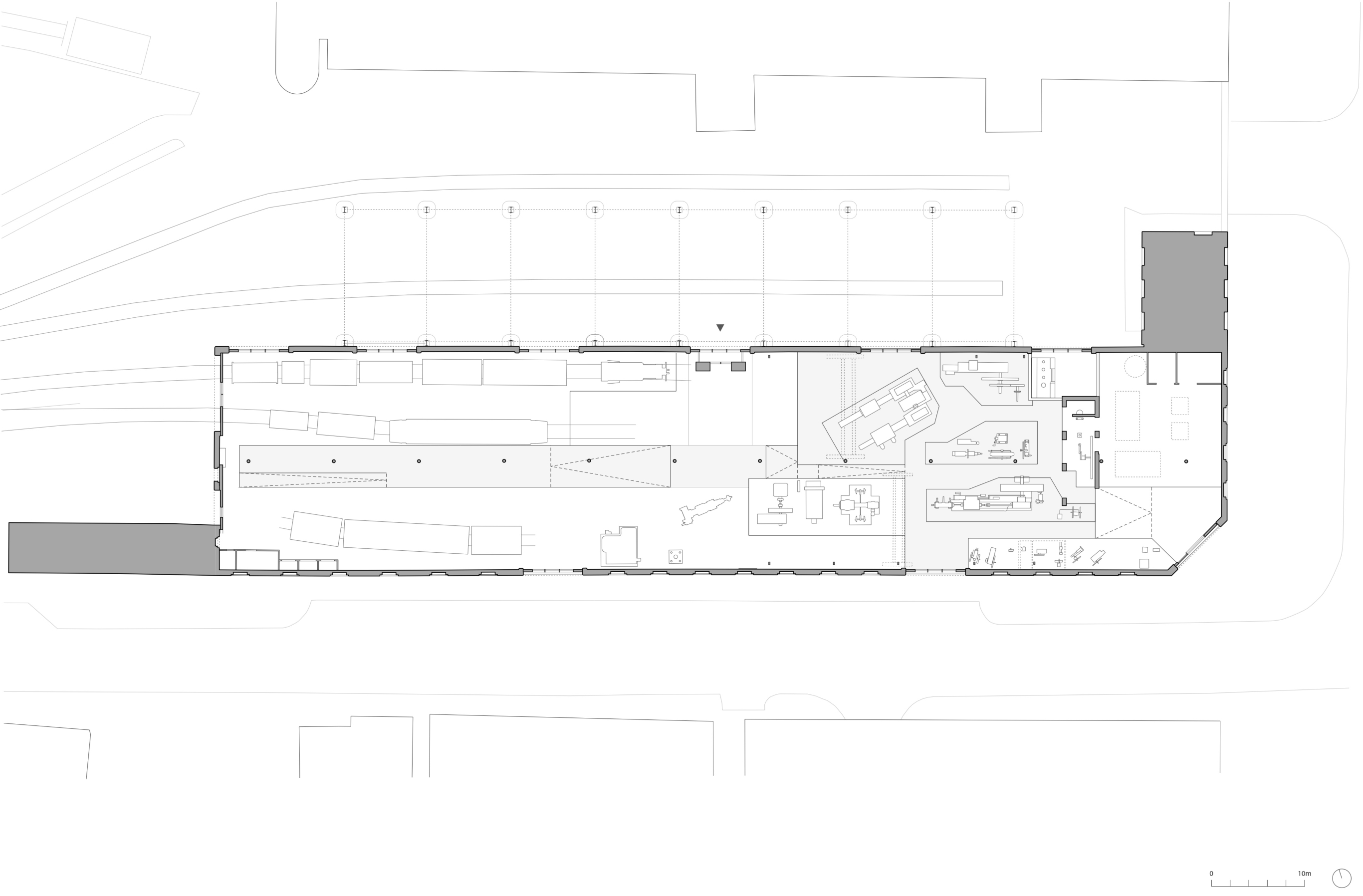

Floor plan.

A raised central platform, historically used for loading and unloading goods, has been reintroduced, restoring the original working diagram of the shed. This platform forms the spine of the visitor route and is flanked by gently ramped walkways that improve accessibility and allow the collection to be viewed from multiple levels, with re-laid cobbles and timber flooring referencing the building’s industrial origins while providing an even surface throughout.

New rooflights bring daylight into the hall while minimising solar gain and UV exposure, part of a vast new roof that reuses most of the original slates, laid over sustainable wood-fibre insulation. Historic brickwork and stone dressings have also been conserved, while new large-format glazing improves daylighting and visibility between the museum interior and the surrounding city.

Recalling the sliding doors of the original railway shed, Smoked Douglas fir ventilation panels have been installed as part of a strategy to improve the building’s environmental performance. A water-source heat pump system and an electric steam boiler have also been installed, both designed by Max Fordham. Drawing on groundwater from the same aquifer that once powered Manchester’s industrial revolution, the new system provides heating for the building and powers its collection of working engines. Together with new insulation, high-performance windows, and energy-efficient lighting, these measures are expected to save approximately 515 tonnes of carbon dioxide every year.

Studio MUTT, a practice local to the North West, worked on the exhibition design for the project. Large circular LED halos and backlit historical images define the main interpretive sections: Powering Lives, Making More, and Connecting Places, while a restrained palette of bead-blasted metal, valchromat, dark-stained timber, and polished steel maintains coherence with the hall’s industrial character.

“Our aim was to curate an experience that was more interactive than traditional exhibition designs,” said the practice. “We wanted the space and objects within it to animate visitors’ journeys with light and texture – to invite them to touch, sit and explore different surfaces and display units as they discover the rich information and human stories within the space. The new structures have been designed to have their own character – a kind of contemporary-industrial aesthetic that we hope will stay with people long after they leave the museum.”

Credits

Client

Science and Industry Museum

Architect, Principal Designer and Lead Designer

Carmody Groarke

Main contractor

HH Smith & Sons

Project manager

Gardiner & Theobald

Cost consultant

Appleyard & Trew

Structural engineer

Conisbee

M&E engineer

Max Fordham with Advisian (borehole consultant)

Heritage consultant

Donald Insall Associates

Planning consultant

Deloitte

Building control

Align Building Control

Fire engineer

Design Fire

Exhibition and interpretation design

Studio MUTT

Landscape architect

Planit with Buttress

Additional images

Jason Sayer2025-10-08T09:27:58+01:00

Related Posts

Source: Architecture Today